About Us

About Mingcome

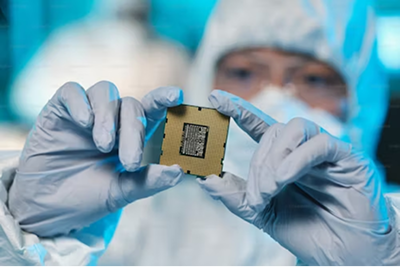

Shenzhen Mingcome Industrial Internet Co., Ltd., founded in 2011, has been committed to becoming a leader in the field of electronic component supply chain management and services, serving more than 50,000 customers. The company is headquartered in Shenzhen, China, with a branch office and a transit warehouse in Hong Kong to ensure efficient and convenient services for global customers. Mingcome attaches great importance to the attraction and cultivation of talents. Our team consists of top talents in the electronic components industry. They are our most valuable assets and the cornerstone of our supply chain management system and excellent customer service. We continuously invest in employee development to ensure that our sales team and logistics support system are always at the forefront of the industry. As a trusted partner in the electronic industry chain, we provide one-stop solutions, including but not limited to demand creation, complete project solutions, professional technical support, efficient warehousing and logistics services, and a convenient IC e-commerce platform. Our services are designed to fully meet the needs of different types of customers, from Original Equipment Manufacturers (OEMs), Original Design Manufacturers (ODMs), Electronic Manufacturing Services (EMS) providers to small and medium-sized enterprises, ensuring that they can obtain the required electronic components and related services to support their business development and technological innovation.

Headquarter:

Shenzhen, China

Number of employees:100+

Service countries and regions:150+

Global customers:50000+

Platform Overview

Mingcome is a one-stop supply chain service platform for electronic components, aiming to fully meet the needs of various customers such as OEMs, ODMs, EMS providers, and small and medium-sized enterprises, ensuring that they can obtain the required electronic components and related services to support their business development and technological innovation. Our platform has a warehouse of over 200,000 square meters, covering nearly 1,000 brands and tens of thousands of part numbers, with a real-time inventory database of over 100,000 items. Relying on this powerful platform and strict procurement, quality, and logistics processes, we help you optimize procurement processes, reduce costs, and ensure efficient supply chain management, allowing you to maintain an advantage in the global market.

200,000+㎡

warehouse space

1000+

brands

10000+

part numbers

1000000+

real-time stock database

Competitive Advantages

Advantage Capability

With a warehouse of over 200,000 square meters, covering nearly 1,000 brands and tens of thousands of part numbers, relying on a real-time inventory database of 100,000+ items, coupled with precise warehouse management and rich supplier resources, the supply is sufficient and stable.

Reliable Delivery

ERP-integrated smart warehouse; real-time inventory sharing with OEMs

Using an advanced ERP intelligent warehouse management system, we share inventory information with multiple original manufacturers and large agents to ensure the accuracy of delivery dates from the source.

Efficient Shipping

Bulk quotation processing; same-day dispatch for orders before cutoff

We can handle a large number of model quotations daily, and orders placed before a specific time are eligible for same-day shipment, improving logistics turnover efficiency.

Comprehensive Catalog

Rapid matching and quoting; BOM list optimization; batch inquiries

The product range is rich, with fast matching speed and quick quotation. It supports BOM table intelligent matching and batch inquiry to meet diversified procurement needs.

Quality Assurance

OEM-authorized channels; IPC-A-610 compliance; X-RAY/decap testing; "10x compensation" for defects

We give priority to original factory agent supply channels and require suppliers to provide product qualification certificates; strictly follow the IPC-A-610 standard, conduct four-level quality control including X-RAY and open cover inspection, and promise "ten times compensation for fake products" for quality problems.

Professional Services

Visual inspection; specialized packaging/labeling

Provide professional incoming appearance inspection, equipped with professional product packaging and labels, to comprehensively ensure the procurement experience.

Service Highlights

Global Presence & Core Capabilities

Developed Global Resource Network

Asia-Pacific hub: MINGFA (HK) INTERNATIONAL CO., LIMITED smart transit warehouse 40% faster cross-border logistics across Southeast Asia and global markets

With the intelligent transit warehouse operated by Hong Kong branch MINGFA (HK) INTERNATIONAL CO., LIMITED as the Asia-Pacific hub, it radiates to Southeast Asia and global markets, improving cross-border logistics efficiency by 40% and building an extensive global resource network.

Close and Efficient Cooperation with Original Manufacturers

Strategic collaborations with 50+ top-tier manufacturers (Infineon, TI, VISHAY, etc.):

48-hour response for shortage materials

95% shortage resolution rate

We have reached strategic cooperation with more than 50 international top original manufacturers such as Infineon, Texas Instruments (TI), and VISHAY. For scarce materials, we can achieve a 48-hour rapid response, with a material shortage resolution rate of up to 95%.

Extensive and Efficient Service Scale

50,000+ enterprise clients (OEM/ODM leaders, EMS providers, SMEs)

ERP/MES systems enable:

✓ Real-time 100,000+ inventory updates

✓ 60% faster BOM matching

✓ 35% annual inventory turnover optimization

We have served more than 50,000 enterprises, including leading OEM/ODM manufacturers, EMS service providers, and small and medium-sized technology innovation enterprises; with the help of ERP+MES intelligent systems, we realize real-time updates of 100,000+ in-stock data, improve BOM table matching efficiency by 60%, and optimize annual inventory turnover rate by 35%.

Technology-Driven Delivery and Quality Control

Full-chain quality control:

✓ OEM authorization

✓ IQC/IPQC dual inspection

✓ MES traceability

✓ 100% genuine components

✓ 24-hour after-sales response

Relying on a 200,000㎡ intelligent warehouse, we support 24-hour rapid prototyping, 99% of orders are shipped within 48 hours, and the sourcing cycle for scarce materials is shortened by 50%; the whole-link quality control is strict, from original factory authorization, IQC/IPQC double inspection to MES code scanning traceability, ensuring 100% genuine products, and after-sales problems are responded to within 24 hours.

Corporate Culture

Customer-centric, innovation as the soul, professionalism as the core, committed to becoming a service pioneer in the electronic components industry. We promise to be based on integrity and quality, and through teamwork and continuous learning, provide customers with excellent electronic components solutions. At Mingcome, we pursue technological leadership and sustainable development, ensuring that every service can accelerate customers' innovation.

- Information